The popularity of ChatGPT continues to ferment around the world. Recently, its latest version, ChatGPT-4, has reached another climax. The iteration speed in just a few months is amazing. As major technology companies gather to seize the new heights of AI innovation, while people marvel at the rapid advancement of technology, a kind of anxiety also begins to pervade: ChatGPT works faster, better than humans, and cheaper than manual labor. Does that mean that many jobs are about to be replaced by smart tools?

In fact, people's thinking about the relationship between machine intelligence and humans is far from starting with ChatGPT, and the anxiety about "being replaced" is not limited to the field of AI. Long before the emergence of ChatGPT, various machine intelligence and automation tools have been widely used in multiple fields. In the process, people have continued to pay attention to the relationship between machines and humans from a broader perspective. In many years of industrial practice, the collaborative robot manufacturer Universal Robots (hereinafter referred to as "Universal Robot") clearly sees that machine intelligence can be used for me, and become a good "colleague" of human beings, helping human beings to make their work easier. Collaborative robots can interact with employees at close range and take over dangerous, difficult, tedious, and intensive tasks. This can not only physically protect the safety of workers, reduce the risk of occupational diseases and work-related injuries, but also allow workers to focus on more valuable work and liberate people. creativity to help workers gain better career prospects and spiritual achievements.

Ensure a sense of safety and reduce risks related to the working environment, the contact surface of the processing object, and ergonomics

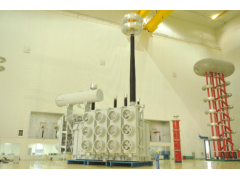

The health risks faced by workers in the workplace first come from the working environment such as dust, chemical reagents, and high pressure. For example, in the production links such as grinding and sandblasting, the working environment is full of dust and noise. Taking grinding as an example, when cleaning burrs for automobile engine cylinder heads and other components, collaborative robots can be used to replace human hands, and the floating grinding head can complete the deburring work of the rocker arm surface and edges, so that workers can avoid inhaling a large amount of dust; another example Yes, disinfection has become the norm in the workplace over the past few years, and the use of collaborative robots for disinfection operations can not only help workers quickly disinfect large areas, but also protect employees from the risk of long-term exposure to chemical agents; in addition, By integrating VR and other technologies into the ecology, it is also possible to flexibly and fully expand the application scenarios of collaborative robots. For example, instead of staff working in high-risk environments such as high-voltage power rooms and nuclear power facilities, employees only need to control them remotely.

In addition to the surrounding environment, the contact between workers and processing objects may itself pose risks such as cuts, burns, and electric shocks. The edges of many parts are very sharp. During the machining, turning and grinding of these parts, workers are easily cut by sharp parts. Another example is that in manual welding tasks, workers often face risks such as burns, electric shocks, and visual impairment. Using cobots for these tasks can effectively reduce such risks. So cobots working in close quarters with workers, does such contact itself pose additional risks? The answer is no. Universal Robots’ patented technology ensures that the collaborative robot will limit its strength when it comes into contact with the worker. Users can also program the Universal Robots collaborative robot to slow down when someone enters the working area of the collaborative robot, and when the person leaves to resume full speed operation.

Even if the risks of the environment and the processed objects are excluded, employees still face another health problem, that is, many movements inevitably do not conform to the principles of ergonomics. Take the waterproof liner on the door during the automobile manufacturing process as an example. When installing the liner, the operator needs to use a force-measuring roller to continuously pressurize it. If things go on like this, it is easy to cause arm joint injuries and even musculoskeletal diseases. Introducing collaborative robots into this work process can not only achieve a repeatability of up to plus or minus 0.05 mm, but also protect the health of the workers. Compared with traditional industrial robots, cobots are very flexible and lightweight, so they can move in a confined space and follow complex paths, avoiding the protruding rivets on the door to ensure that the gasket is completely sealed to prevent water leakage.

Create a sense of accomplishment, help workers transform into high-skilled talents, and seize career opportunities in new positions

After gaining a sense of physical security, employees also have higher-level needs, and they need a sense of spiritual accomplishment. After collaborative robots take over tedious and dangerous basic tasks, workers can focus on higher-value tasks and seek new knowledge and skills. The data shows that while machine intelligence replaces basic tasks, it also creates many new jobs and catalyzes the demand for highly skilled personnel. Data from the World Economic Forum [1] predicts that by 2025, the development of automation will create 97 million new jobs. At the same time, the data show that in recent years, the employment rate of high-skilled talents in China has remained above 2 for a long time [2], which means that a technical and skilled talent corresponds to at least two positions, which shows the degree of demand.